Chapter 4

.....standing

rigging

The

STANDING RIGGING consists of the wires that hold up and support

the mast. Because the mast is in compression and tends to buckle

or bend, the standing rigging helps to control the bending. Some

small sailboats do not use any standing rigging, and these are

said to have free standing unstayed masts (see Figs.2-4 and 2-5).

The calculations and methods of figuring the strength of spars

and associated rigging are very technical and involved, and

should not be undertaken by the novice. Rig your boat as the

designer or manufacturer recommends; don’t make shortcuts.

The material used for the standing rigging is wire rope, usually

made from stainless steel, although regular or galvanized steel

wire rope is available. Wire rope is measured by the diameter and

specified by the composition of the wires used to make up the

wire rope (see Fig. 4-1). For example, wire rope designated 1 x

19 would consist of one wire made up of 19 strands. This type is

the most common for standing rigging because it is not flexible

and is strongest. Another type designated 7 x 19 consists of 7

ropes each consisting of 19 strands. This type, while not as

strong, is used where flexibility is important. On boats which

use wire rope halyards, the 7 x 19 wire rope is utilized.

|

| FIG. 4-1 -Wire rope

for rigging is generally in two configurations; stiff and

flexible. FL-. 4-1 'a’shows a length and section of

I x 19 wire rope which is considered stiff. The length is

made up of 19 individual strands and is the type usually

used for stays. Fig. 4-1 ’b’ shows a length and

section of 7x 19 wire rope which is a flexible type

commonly used - for halyards. The length is made up of

seven ropes each consisting of 19 strands. |

FIG. 4-2 & 4-3-Common methods

of joining fittings to wire rope. Fig. 4-2 'a’shows

a swaged ball which can be readily connected to a shackle

or forked jaw. Fig. 4-2 ’b’ shows a swaged fork

or jaw and a swaged eye commonly used to connect to

tangs, turnbuckles, chainplates, etc. Fig. 4-3 shows a

typical Nicopress fitting. The wire rope passes around

the thimble and the end is clamped with the special clamp

shown. Flexible wire rope is best used with this type of

fitting. |

Obviously

fittings must be attached to the wire rope for it to do a job,

and these fittings can be attached by any of several methods. One

method is to SWAGE the fitting to the wire rope. Swaging means

that the fitting is compressed cold between a pair of dies., Fig.

4-2 shows some swaged fittings commonly used on small sailboats.

Another method is the NICOPRESS fitting, a patented method which

uses a sleeve wrapped around the wire forming an eye, and

gripping both strands together, as shown in Fig. 4-3. A special

vise-like tool is, used to clamp the junction tight. With the

Nicopress junction, a THIMBLE (grooved metal ring in the looped

eye to prevent chafe) must be used. Because of the bend required

in the wire rope at the thimble, flexible wire rope such as 7 x

19 should be used for ultimate strength at the junction.

Special

patented-type swageless terminals are also available for joining

fittings to wire rope. One type forms a mechanical joint by use

of a sleeve barrel fitted over the wire rope and a plug which is

inserted into the end of the wire rope. A socket with the fitting

attached to it is screwed into the sleeve. The plug inside the

sleeve is compressed tightly against the wire rope strands,

thereby forming the connection. With this type of junction, the

fittings can be disassembled from the wire rope and reused,

whereas the swaged fitting cannot. While this type of fitting can

be done with ordinary hand tools, a great deal of the strength of

the fitting depends on the ability of the person making the

junction. Usually swageless fittings are bulkier and heavier than

swaged or Nicopress fittings, although arguments exist as to

which is stronger. In all cases, the strength of the fitting

depends on the quality of the craftsmanship.

A

method rarely used today for attaching fittings to wire rope is

the zinc socket type connection. This method uses molten zinc

poured into the fitting to hold it in place. While still used on

some “character” boats and commercial craft, it is

considered less reliable than any of the above methods.

STAYS

|

| FIG. 4-4 Typical standing rigging configurations.

The rig in "a" uses jumper struts which are

splayed out diagonally from the mast in order to clear

the shrouds. The jumper stays reinforce the mast from the

pull caused by the mainsail, as the forestay does not go

to the masthead. If the jib is used, this boat would be a

jibhead rig. The rig shown by "b" is a typical

masthead sloop rig common on boats about 17' and larger.

The rig shown by "c" is a typical jibhead rig.

The bridle on the backstay is optional and is usually

used to provide clearance for an above deck tiller. This

arrangement could also be used to provide an adjusting

mechanism for varying backstay tension as is common on

competitive sailboats. Spreaders and additional shrouds

may be used as required on some jibhead rigs. |

The

STAYS are wire ropes that support the mast in a fore and aft

direction. Technically speaking, any wire that helps support the

mast can be called a stay, but in our discussion, we will refer

to those at the side of the mast as specifically SHROUDS,

described later. Reviewing Fig. 4-4 will aid in following this

discussion on stays.

The

FORESTAY supports the mast from the forward side and is usually

attached to the hull near the forward end of the boat. On a

jibhead rig the forestay is attached to the mast about 7/8 the

way up from the base. On a masthead rig the forestay attaches to

the masthead. On catamarans because of the twin hulls, the

forestay often intersects with a BRIDLE, and the bridle is

attached to the bow of each hull. A bridle is a line secured at

each end with attachment by another line to the middle of the

bridle. Some catamarans use a beam between the hulls at the bow

and attach the forestay to this beam at the middle in the

conventional manner. On single hull boats, the forestay is

connected to the hull at the STEMHEAD (forward point of the hull

usually at the deck). The forestay must be capable of

withstanding considerable strain. The other stay on masthead rigs

that complements the forestay is the BACKSTAY. The backstay

supports the mast from the aft side, and runs from the masthead

to the aft end of the boat. Some backstays connect to a bridle

arrangement such as used on the forestay of catamarans previously

mentioned. When the bridle is used on the backstay, in most cases

it is to allow clearance at the tiller where it pivots across the

deck. A backstay is not usually required on small jibhead rigs,

but is virtually always used on masthead rigs. Not all backstays

are fixed in position. Those that are not, are called

“running backstays” and are usually associated with

boats of a size not covered in this book.

The

stays that support the mast at the sides are called SHROUDS, and

it is not correct to call them “side stays” or any

other name when they are being referred to specifically. As

mentioned previously, not all boats use stays, but boats using a

forestay will invariably have at least one shroud per side. When

a backstay is not used, the shrouds must take most of the forward

tension set up by the forestay, and hence are usually set

somewhat aft and outboard of the mast. With jibhead rigs on small

boats, there is usually only one shroud per side, attached part

way up the mast at some predetermined point. The shrouds are

attached to the hull by using CHAINPLATES (shown in Fig. 7-1). Chainplates are straps of metal

bolted to the hull to take the strain transmitted by the shrouds.

When

the mast requires additional support, two or more sets of

spreaders are required, especially on boats which also use a

backstay. The set of shrouds which pass through or across the

spreader tips and attach to the masthead are called the upper

shrouds. They are usually located in line with the side of the

mast functioning along the gunwale or rail of the hull or cabin

side. The shrouds that join to the mast at the spreader

connection are called the lower shrouds, and may connect to the

hull forward or aft of the upper shrouds. In some boats it is not

uncommon to use two sets of lower shrouds, joining the hull at

least several inches apart from each other outboard. The reason

shrouds should preferably not junction at a common point is in

order to distribute the mast loads over a greater area of the

hull.

The

shrouds usually attach to the hull via the chainplates, while the

forestay attaches to the stemhead fitting, and the backstay to a

backstay tang or chainplate. At the spreaders, the upper shrouds

should be protected from chafing where they move at the spreader

tips. This is best accomplished by-using non-chafing spreader

tips. The spreader tips themselves should be rounded or smoothed

so as not to chafe or snag the sails.

|

| FIG. 4-5 The turnbuckle allows stay tension to be

adjusted. This turnbuckle fastens to the chainplate with

a jaw fitting and pin, and is swaged to the wire rope

stay. Once adjusted, turnbuckles should be locked in

position to prevent them from unscrewing. This is also

important during transport and storage as it is easy to

lose turnbuckle parts and not always easy to replace

them. |

As

mentioned previously, sometimes supplementary stays are required,

and these are usually the diamond stay or jumper stay. They use

the same type of wire as other stays although perhaps not as

heavy, but they never junction with the hull. All stays and

shrouds should have some means of adjustment, and several methods

for providing this are commonly used. The most familiar item is

the TURNBUCKLE (a fitting with a screw link for tightening the

stay) which is available in a variety of types. A typical

turnbuckle is shown in Fig. 4-5. Turnbuckles can be attached to

the wire rope stays with either a swaged fitting or Nicopress eye

and thimble. If the unit is swaged, the turnbuckle must be free

to pivot so no bending will occur where the wire enters the

swaged area. This is accomplished by using a swivel connector

which is integral with the turnbuckle. All turnbuckles should

have a means of locking them once the stays have been adjusted.

Turnbuckles usually have a jaw and pin which connects them at

their lower ends to the chainplate or deck fitting. Another

method of adjusting stays and shrouds is with a STAY ADJUSTER

(see Figs. 3-4 and 6-2). The stay adjuster consists of a

shaped section of metal, usually stainless steel, with several

holes for adjustment. The lower end of the stay adjuster is

pinned to the chainplate, while the stay is attached with a pin

through any one of the holes in the stay adjuster which give the

proper adjustment to the stay. Stay adjusters are less costly

than turnbuckles, and when used, no turnbuckle is required for

the respective stay. However, stay adjusters are not capable of

varying tension on the mast as are turnbuckles, and for this

reason, it is common on simple rigs using three stays to use stay

adjusters with the shrouds, and a turnbuckle on the forestay

which is used to vary the tension once the proper adjustment is

set up in the stay adjusters. Once set up, there is no need to

ever readjust the stay adjuster, even though the slack stay

adjuster to leeward when sailing on a tack could be set up tauter

(assuming both sides are readjusted equally) thereby putting more

tension in the rig. On rigs with multiple shrouds plus forestay

and backstay, it is desirable to use turnbuckles on each stay

instead of stay adjusters in order to set each stay properly. It

is possible to connect stay adjusters to deck plates in lieu of

the chainplate thereby eliminating the need for the chainplate.

But, chainplates are more desirable as they distribute the

strains imposed by the stays over a larger area.

Another

more elaborate device for stay tension adjustment is somewhat

like the stay adjuster, but consists of a lever actuator which

gives extra power in tensioning the stay. These are called

HYFIELD LEVERS (Fig. 4-6) which come in a wide variety of types

and sizes, and are often used for tensioning problems other than

with stays. Hyfield levers are usually associated with

competition-type craft where immediate stay adjustment is

required.

|

FIG. 4-6 Hyfield levers allow tension to be

varied, such as along stays. Many types and sizes are

available, but are usually only used on competition

boats. |

A

last means of attaching stays is by means of a simple rope

lashing. The rope is merely lashed through rings or thimble eyes

attached to the chainplate or bridle on catamarans, and at the

lower ends of the stays. Rope lashings should be polyester lines

which will not stretch, and should be of ample size. Stays can be

attached to the mast in several different manners, part of which

may be dictated by whether the mast is made of wood or aluminum.

In most cases the stay must be fitted with some form of an eye

which will allow it to be attached to the mast via a fitting such

as the tang or masthead. As shown in Figs. 4-2 and 4-3, these

methods can be a conventional eye, fork or jaw, or a ball joint

connected to a fork strap or eye strap. On masthead rigs, it is

desirable to give the backstay and fore stay a universal action

at the masthead attachment. This can be done with the ball joint

type fitting, or by the use of a TOGGLE (a swivel connector as

shown in Fig. 3-9). The reason is to

prevent bending of the wire rope where it joins to the fitting

attached to the wire rope.

Chapter 5

.....running

rigging

|

| FIG. 5-1-This neatly rigged boat is

ready to receive the sails. The running rigging is

clearly shown. This mainsheet rig is like that shown by

Fig. 5-4. The clew outhaul slides on a track with a line

securing it to a jam cleat on the side of the boom. The

aluminum tubing boom is held in position by the main

halyard. The main and jib halyards are neatly coiled in

position on the mast. Note the tracks with sliding cam

cleats on each side of the centerboard for controlling

the jib sheets. |

INTRODUCTION

The

RUNNING RIGGING consists of the lines used for hoisting and

controlling the sails directly, or indirectly such as through

control of the boom. The boat in Fig. 5-1 shows many of the lines

used for the running rigging in position. The running rigging

moves about the boat, or can be moved. The LINES are usually made

from ROPE. Once the rope becomes operational in the boat, it is

then referred to as a “line”. This then is the

difference between line and rope. Most lines on small sailboats

are made from synthetic twisted or braided rope, such as

polyester or polypropylene. Nylon is usually not a good line

because it stretches too much. Ropes of natural materials such as

hemp are seldom used anymore. Wire rope is sometimes used for

some running rigging, but must be connected to rope at the moving

ends that must be handled. A type of rope made especially to be

easy on the hands is called “YACHT BRAID” or other

similar proprietary name, and is more costly than the normal

braided line. Rope sizes are commonly noted by the approximate

diameter of the rope, even though it was once common to give the

size by the circumference.

HALYARDS

The

lines used for hoisting and lowering the sails are called

HALYARDS. The halyards run up and down the mast across a sheave

(pronounced “shiv”) at or near the top of the mast.

Halyards that are outside the mast are called

“external” halyards, and those that run inside a hollow

mast are called “internal” halyards. Halyards on small

boats can be made of rope, and often stainless steel wire rope is

also used. When wire rope is used, it should be the flexible type

such as 7 x 19. In the case of wire rope halyards, a portion of

braided or twisted rope must be attached to the running end so

the crew can handle the halyard without injuring their hands. The

braided rope is then attached to the wire rope either with a

Nicopress eye, or by a special splicing. On large boats, special

halyard winches designed for wire rope preclude the need for a

rope tailing.

Several

methods are used to attach the halyards to the head cringle of

the sails. Probably the most common method is the use of a

SHACKLE, a “U”-shaped fitting with an openable pin at

the open portion of the “U” which passes through the

head cringle (see Fig. 6-2). The

halyard is attached to the shackle either with a spliced eye,

Nicopress eye, or it is sometimes merely tied by a knot. A better

method when wire rope is used is to use a ball joint with the

shackle fitted onto the wire rope halyard before the ball has

been swaged on (see Fig. 4-2

‘a’). When wire rope halyards are used with a ball

joint, a HALYARD HOOK should be used near the masthead. This

fitting prevents hoisting the sail beyond a predetermined point

up the mast. Sometimes an additional halyard hook is located near

the mast base for the running end of the wire rope halyard with

another ball swaged at this end to secure the halyard.

| Another method used to attach halyards to

sails is with BRUMMEL HOOKS (as shown in Fig. 5-2). These

are special patented fittings used in pairs which allow

quick attachment once you get the hang of using them. The

Brummel hooks come in a wide variety of sizes and types

which can be used for other situations as well as with

halyards. One hook passes through the cringle at the head

of the sail, and another goes through the eye at the end

of the halyard, or can be merely knotted to the halyard.

The two connect with a twist of the wrist. |

FIG. 5-2-Brummel hooks are patented

fittings used in pairs. They are used to secure lines

together or lines to other items such as sails. A twist

of the two hooks is all that is required to join or

release them. |

SHEETS

The

lines used to control the trim or position of the sails are

called SHEETS. The line used to control the mainsail is called

the MAINSHEET, and the line used to control the jib is called the

JIB SHEET. Rope is used for the sheets, and “yacht

braid” type is often used because it is easier on the hands

and does not kink or jam as easily as twisted rope. Because the

force of the wind on the sails is often greater than the strength

of the crew, it is often necessary for the sheets to have a

built-in “mechanical advantage.” This is where the

various blocks (or “pulleys”) and winches come onto the

scene in various configurations to ease the work of the crew.

|

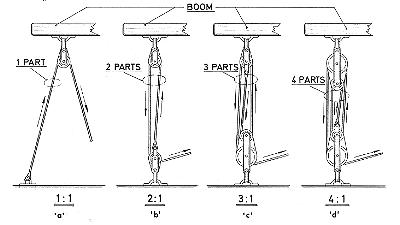

| FIG. 5-3 - Various tackle

configurations. The power of a tackle depends on the

number of "parts" in the tackle. Actually, 'a'

is not really a tackle as the block merely changes the

direction of the line, thereby affording no gain in

power. Fiddle blocks are shown for clarity where two

sheaves are used, though double blocks, with side by side

sheaves, would give the same result. The arrows show the

direction the line will move when pulled. |

When the sheets are lead

through a system of blocks, a TACKLE is formed that,

depending on the number of “parts,” will

decrease the effort required to do the work. This is

called “mechanical advantage” and is shown by

Fig. 5-3. All main sheet configurations are nothing more

than variations on these basic tackles, even though the

location of the various blocks may disguise the number of

parts used in the tackle. In figuring a tackle, it is

usual to deduct 10% from each “part” per block

to allow for the friction caused at the sheave in the

block. Also note that the more parts in a tackle, the

more line you must have and consequently the more line

you will have to pull through the tackle to move the

object a comparable distance.

Sheet rig types come in an infinite

variety of configurations, and some of the more common

main and jib sheet rigs have been shown in Figs. 5-4

through 5-13. To run the sheet through the blocks is to

REEVE the sheet, and it is a good practice to knot the

running end of all sheets so they will not inadvertently

pass through and out the blocks, causing loss of control

of the sails.

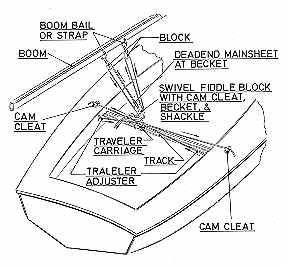

Note that in many cases the mainsheet

forms, or is used in conjunction with, the TRAVELER. The

traveler lets the mainsheet rig or unit move or

“travel” from one side of the boat to the

other. Travelers can range from the combination

mainsheet/ traveler type, or a simple length of line, or

very elaborate fittings complete with tracks using blocks

with ball or roller bearings and lines to control them.

|

FIG. 5-4 - Ratio 2:1. A simple

mainsheet set-up which uses a rope or wire rope traveler.

Although the traveler is shown deadending to eye straps,

one end could be made adjustable by belaying to a jam

cleat. The mainsheet can be held by hand or a block or

cam cleat can be used as shown in Fig. 5-5.

FIG. 5-5 - Ratio 3:1. The mainsheet is

used as the traveler in this rig.

|

FIG. 5-6 - Ratio 2:1. This mainsheet is

also used as the traveler, but requires at least some aft

deck area. The main feature of this layout is the minimum

of hardware required. Because the sheeting lead on the

boom is at the aft end, roller reefing can easily be

incorporated by hanging the side shackle block from a

swiveling tang on the end of the boom. |

FIG. 5-7 - Ratio 4:1. This mainsheet

rig is handy to use where roller reefing is desired. It

would be possible to mount the lower fiddle block to a

track so it could to move each side with the boom, acting

as a traveler. If roller reefing is not used, the

mainsheet arrangement could be located at some location

along the boom, although this would increase the effort

required to move the boom. |

FIG. 5-8 - A system similar to Fig.

5-7, but using a rope or wire traveler similar to Fig.

5-4. This arrangement could also be located at the end of

the boom for use with roller reefing. A cam cleat could

be used at the swivel block so that the line need not be

hand held. |

FIG. 5-9 - A rather elaborate system in

that the traveler can be adjusted with lines each side

via cam cleats. The fiddle block with cam cleat is used

so that the line need not be hand held. |

| Winches ease the work

required in pulling or trimming the sheets, such as on

jib sheets, as in Fig. 5-13. A winch gains mechanical

advantage due to its gear ratio, diameter of the handle,

and by the drum diameter of the winch. To determine the

mechanical advantage (or power ratio), use the following

formula: Radius of handle divided by the Radius of the

drum X the Gear ratio = Power ratio. This means that

power can be gained by either increasing the gear ratio,

or radius of the handle, or decreasing the drum radius,

or a combination of all three. Usually the drum radius

should not be decreased because the winch will then do

the work more slowly. On small boats such as being

discussed here, most winches will not have gears and are

thus referred to as “direct drive” winches such

as shown in Fig. 5-14. Often used on small boats are

winches which do not have handles either, and these are

called “snubbing” winches (Fig. 5-15). Winches

are usually relatively expensive items, and because

mechanical advantage can be gained by other means, they

are considered “deluxe” equipment on boats

under about 25' in length. |

FIG. 5-14 - This is a typical example

of a ratchet winch, which uses a

handle, for controlling jib sheets. |

FIG. 5-15 - A typical snubbing winch

as used for jib sheets on

small sailboats. No handle is used. |

| FIGS. 5-10 through 5-13

show various jib sheet configurations. Jib sheets are

usually two part lines secured at the mid length to the

jib clew cringle usually via a shackle. This means that

the hardware to control one side of the jib sheet will be

duplicated for the other side; in other words, each side

of the boat will have the fittings shown. |

FIG. 5-10-A fairlead on a slide allows

adjustment of the jib sheet lead point via the track. The

sheet can be hand held or belayed to a cleat at some

convenient point. |

FIG. 5-11-Similar to the foregoing but

the line is belayed with a cam cleat mounted directly on

a slide which runs on the track. |

FIG. 5-12 - This system provides a

power advantage of 2 to I (before allowing for fiction)

to the jib sheet. The pad eye is mounted outboard of the

track and two bullet blocks are shackled to the sail (one

for each sheet for each side of the boat). The line then

passes through a fairlead slide on a track and then aft

to a jam or cam cleat. Optionally, the cam cleat could be

mounted on the slide as for Fig. 5-11. |

FIG. 5-13 - This jib sheeting method

gains power through the use of a winch. The power of such

a rig is directly dependent on the power of the winch

that can be varied to suit. A fairlead on a slide could

be used on the track, however, the swivel block reduces

friction and chafe. A snubbing winch is shown in this

example, although a winch with a handle can be used. The

line must be belayed to a cleat beyond the winch. Note

that the lead from the swivel block to the winch is

fairly horizontal, as it should be. |

JIB SHEET LEAD

The sheet used to control the jib must be

lead to a point on the boat that affords optimum setting

of the jib (if one is used). If a Genoa jib is used, a

separate sheet lead must be determined for this sail

also. Since the jib sheets are in two parts (one for

starboard, and the other for port), a lead point will be

located on each side of the boat. In determining the lead

points, the designer probably uses a formula similar to

that shown in Fig. 5-16, which is at best always an

approximation. Because methods used to determine jib

sheet leads are approximations, and because no two sails

will trim the same, it is best to make the sheet lead

point adjustable by using lengths of tracks and sliding

fittings attached to them. Another method for determining

the jib sheet lead, at least on small boats, is to

actually sail the boat with the jib in position and

thereby determine the optimum setting in actual use. When

the optimum point has been located, mark with a pencil

and attach the appropriate fittings to the deck.

|

FIG. 5-16 - A common method used for

locating the jib and Genoa sheet leads is graphically

shown. The results are usually acceptable, but it is wise

to use tracks so minor variations in sheet lead can be

made. |

DOWNHAULS AND BOOM VANGS

Not all boats use downhauls or boom

vangs, but they are used enough to warrant discussion. A

DOWNHAUL is merely a line used to haul down on something,

usually the tack of the sail, or the boom where the tack

of the sail is located (see Fig.

3-12). A boom downhaul fitting or eye is often a part

of the sliding gooseneck, to which the downhaul is

attached to prevent the gooseneck from sliding up the

mast. Once the sail has been hoisted with the halyard and

pulled taut to a cleat, the downhaul can be used to gain

further tension along the luff of the sail by pulling

down and making fast to a cleat. Naturally, a similar

downhaul could be used on the jib. A special type of

downhaul called a “CUNNINGHAM” requires that

the sail have an additional cringle usually located

several inches above the tack cringle. The

“Cunningham” is usually used on competition

boats where more shape control of the sail is desired

along the luff, but because of the racing rules, the boom

cannot be hauled down below a certain pre-designated

point.

A BOOM VANG (also called a “go

faster” and “kicking strap”) is a device

that performs several functions. The boom vang is a

tackle arrangement (see Figs. 5-17 and 5-18) connected at

one end to the mast near its base, and with the other end

preferably about 1/3 the distance of the boom aft of the

mast. The boom vang helps take the undesirable

“twist” out of the sail on all courses off (or

away) from the wind, flattens the mainsail on a tack

(sailing in the direction of the wind), and prevents the

boom from lifting in case of accidental jibes (the boom

moving rapidly from one side to the other when sailing

downwind). |

|

|

| FIG. 5-17 & 5-18 -

Two boom vang tackles with fittings. The upper block is

attached to the boom, while the lower block is fastened

to the mast base or near the mast base on deck. These

boom vang tackles could also be used for mainsheet rigs

if desired. Fig. 5-17 (left) has a power ratio of 3 to 1.

Fig. 5-18 (right) has a power ratio of 4 to 1. |

HOW TO FIGURE A TACKLE

In order to figure a tackle to control a

mainsail, for example, you must first know the area of

the sail. Once the area of the sail is known, figure the

“load” caused by the wind on the sail. In

figuring for a mainsail which has the mainsheet lead at

the end of the boom, figure wind load by multiplying the

sail area by 1.5 lbs. per square foot. If the mainsheet

leads to the boom midpoint, multiply the sail area by 3

lbs. per square foot. (For figuring the jib or Genoa,

also multiply by 3 lbs.) Actually, these factors are only

estimates by rule-of thumb and allow a safety factor in

consideration of varying sailing conditions, rig designs,

and wind forces up to 20 knots, but the results will

usually be close enough.

If, for example, a mainsail has 100

square feet of area, the mainsheet load at the end of the

boom would be 100 square feet multiplied by 1.5 lbs. and

would equal 150 lbs. Obviously, in order to control this

sail it would require 150 lbs. of “pull” at

times on the sheet. So to reduce this effort, we devise a

tackle. But how many “parts” should be included

in the tackle? Again a rule-of-thumb is used which says

that most people can pull 30 to 50 lbs. on a line BY

HAND. If using a cam cleat on the end of a line, this

figure can be increased, say up to 75 lbs. or more for

he-man types! But, in most cases, it is good to stick to

the 30 to 50 lb. range, if practical.

The ability of a tackle to do work

depends on the number of “parts” or lengths of

line BETWEEN the blocks as shown in Fig. 5-3. The more

parts, the easier will be the job, but consequently the

longer will be the length of line AND TIME to move the

load or boom a given distance. To determine the effort

required on the line when rigged in the tackle, divide

the total wind load by the number of parts in the tackle.

For example, using our 100 square foot sail, divide the

wind load of 150 lbs. by 4 (if we wanted a 4-part tackle)

and arrive at 37.5 lbs. of pull required to move the boom

or load. However suitable this figure may be, we must

DEDUCT a certain amount that will be lost due to friction

caused by the sheaves in the blocks, and other factors

that take away from our gain in mechanical advantage.

Again another rule-of-thumb is used which figures a 10%

loss for every sheave used in the tackle. Therefore, with

a 4-part tackle which has four sheaves, multiply each

sheave by 10% for a total of 40%, which is then

multiplied against the total wind load (40% x 150 lbs.)

for a total of 60 lbs. lost to friction and other losses.

(While the 10% figure is not technically exact, it is

close enough to use as a practical short cut, and it does

yield conservative results.) To the result (60 lbs.) add

150 lbs. (wind load) for a total load of 210 lbs. Divide

this figure by the number of parts in the tackle (4) for

a result of 52.5 lbs., or just about the maximum for

holding a sheet by hand in a 20 knot wind. If we use a

jam cleat to secure the sheet, this tackle will prove

sufficient to do the job under just about all conditions

short of having to reduce sail area. This example can be

used to figure other tackles as well. In summary:

SAIL AREA X FACTOR (1.5 OR 3) divided by NUMBER OF PARTS

IN TACKLE EFFORT (BEFORE FRICTION LOSS). To figure

power loss in tackle:

WIND LOAD X 10% PER SHEAVE FRICTION LOSS; WIND LOAD +

FRICTION LOSS = TOTAL LOAD IN LBS.

To figure load on end of sheet which crew must handle:

TOTAL LOAD IN LBS. divided by NUMBER OF PARTS IN TACKLE =

LOAD IN LBS. AT END OF SHEET.

|

Chapter 6

.....deck

fittings

INTRODUCTION

"Deck

fittings” is a general classification for all hardware used

with the running or standing rigging, as well as the spars, even

though the fittings may not always be mounted to the deck. Deck

fittings may be located on cabin tops, cockpit members, and

centerboard trunks as well. There are endless numbers and styles

of fittings available, and the number of new fittings and

inventions, plus modifications to existing ones, is constantly

increasing. We will attempt to describe those which are most

generally used in the size sailboats under discussion.

BLOCKS

A

BLOCK is a wood, metal, or synthetic casing that contains one or

more grooved pulleys called sheaves. Blocks are the primary

pieces of equipment in the running rigging, and come in a wide

variety of sizes and types. Besides adding mechanical advantage

to the running rigging, blocks are used to change direction of

the line passing through them. Conventional blocks must be

attached to something in order to work, and the most common

method used is by a shackle that is usually an integral part of

the block. Three types of shackles are used; front, side, and

swivel shackles. Fig. 6-1 shows the difference between front and

side shackles, but the trend is to fit blocks with adjustable

shackles which can be mounted either with a front or a side

shackle using just one block or with a swivel shackle. A front or

side shackle is used to keep the block in one position or plane

of reference, whereas a swivel shackle allows the block to turn

to any position.

|

|

| FIG. 6-1 - The anatomy

of blocks. Not all blocks have all of the above parts.

Some blocks have shackles that swivel or are adjustable

to either side or front shackle locations. A block with

one sheave is a single block; with two sheaves a double

block; etc. |

FIG. 6-2 - This drawing shows hardware

items and how they function on the boat. Note that all

lines used to control various functions of the rig lead

to a point convenient to the helmsman. |

A BECKET is often fitted to

blocks at the opposite end of the shackle. The becket is a

fitting on the block onto which a line with an eye, or another

fitting such as a hook, can be attached, as in forming a tackle.

Some of the common blocks are illustrated in Fig. 6-2.

A

FIDDLE BLOCK as shown in Fig. 6-3 contains two sheaves, one above

the other with one usually smaller in diameter than the other. It

looks like a “fiddle.” A fiddle block may have a becket

as well as a cam cleat arrangement (see Fig. 6-4) for use with

main sheets and boom vangs. A CHEEK BLOCK (see Fig. 6-2) lays

flat to its base, with the base being fastened to the deck. The

cheek block is commonly used to change direction of a line.

SWIVEL DECK BLOCKS (Fig. 6-5) have a base which fastens to the

deck and allows the block to assume a near-vertical position

capable of swiveling in any direction. A BULLET BLOCK is a single

block of small size which usually has no shackle (see Fig. 5-12).

The top of the bullet block is usually shaped to attach through

the eye of a line, an eye strap, or to a boom bail. A TRAVELER

BLOCK is one with two sheaves, one above the other, and with one

at right angles to the other (see Fig. 6-2). One sheave is for

the traveler, and the other for the mainsheet. No shackle is

used. Sometimes two bullet blocks interlocked at the straps can

be made to form a traveler block.

When

wire rope is used, blocks must be used which are intended for

this material. Some blocks are available which have sheaves

suitable for use with both rope and wire rope. The sheaves of

these blocks have a regular groove for the rope, and a narrower

but deeper groove within the regular groove to suit the wire

rope.

FIG. 6-3 - A typical example of a

fiddle block. |

FIG. 6-4 - A fiddle block with a

built-in cam cleat which can be used with various

mainsheet and boom vang rigs. |

FIG. 6-5 - A swivel deck block allows

the sheave to turn to the proper direction for the line

leading through it. |

FIG. 6-6 - The cams of the cam cleat

hold the line but it can be quickly released with a flick

of the wrist. |

FIG. 6-7 - This is the deluxe mainsheet

cam cleat which swivels, allows a fairlead to the main

sheet and belays the line so it does not have to be hand

held.

photo courtesy Schaefer Marine Products |

FIG. 6-8 - A swiveling mainsheet cam

cleat mounted on a bracket on the daggerboard trunk. The

mainsheet passes through the into the cam cleat. The

looped wire (right) prevents the line from jumping out of

the cleat when released. Note the pin on the daggerboard

trunk to “lock “ the daggerboard in position. |

CAM CLEATS

A

CAM CLEAT is a fitting used to belay (halt and secure) a line.

The line passes between two serrated cams which allow the line to

be pulled through in only one direction. To release the line, it

is pulled up and out of the cams. Fig. 6-6 shows a typical cam

cleat. Cam cleats often have a fairlead to guide the line into

the cams. Regular cam cleats are normally mounted flat to the

deck. A cam cleat arrangement is often attached integrally to a

fiddle block for adjusting a boom vang or main sheet. A deluxe

fitting is a swiveling mainsheet cam cleat (Figs. 6-7 and 6-8)

which comes with a block and a fairlead to change direction of

the mainsheet, leading it into the cam cleat. The benefit of this

fitting is that the helmsman need not hold onto the mainsheet,

but it can he released in an instant by giving it a yank upwards.

It also swivels so the sheet will be at hand on any tack.

FIG. 6-9 - A selection of tracks and

slides. Some are of stamped metal while others are

extruded; aluminum, stainless steel, and plastics are

common materials used. The slides shown are designed to

fit the tracks. |

TRACKS

TRACKS

are formed metal or plastic rails on which fittings can be

attached to allow them to move. A piece of track is used where it

is desirable to have the position of the fitting adjustable.

Tracks can also be used to attach the sail to the spars in some

cases. Tracks are commonly used for the jib and Genoa sheet leads

which pass through fittings attached to slides moving on the

tracks. These fittings can range from a fairlead slide, or a

block on a slide, or even a cam cleat on a slide. Some typical

slides and tracks are shown in Fig. 6-9. Tracks are also used for

the clew outhaul slide and for sliding goosenecks. When the

gooseneck mounts to a slide, a downhaul is used as well to allow

for adjustment. Jib and Genoa tracks, and tracks used for

travelers should be fitted with stops at the ends to prevent the

fittings from sliding off the tracks. In selecting tracks,

remember that the fitting to be used must be made to fit the type

track being used.

CLEATS, FAIRLEADS, AND EYES

CLEATS

(Fig. 3-19) are fittings to which

lines are belayed and secured. With small sailboats, a common

cleat is a JAM CLEAT. These allow a line to be taken through or

turned around the jam cleat in such a manner so that it will not

slip free. Jam cleats are commonly used to secure halyards and

sheets. Many kinds of patented-type jam mechanisms are also

available which are often referred to as “jam cleats”

because they perform the same function. FAIRLEADS are actually

any fittings which give a “fair lead” to any line (see

Fig. 6-2). Fairleads are usually eye-shaped fittings which

minimize or prevent chafing of the line which passes through it.

Fair fairlead (left) and leads usually change the direction of

the line passing through them as well. As noted previously, a

block can be used to change the direction of a line also, thereby

making it a type of “fairlead” too. Fairleads can be

fixed to the deck, swiveling, or mounted on tracks.

EYES

such as PAD EYES, DEAD EYES, and EYE STRAPS are used to secure a

line or a fitting to the boat (see Fig. 6-2). Many types are

available to fulfill a variety of functions. Pad eyes, when

fitted with a shackle, can secure a block to the hull and allow

it to adopt the right position for proper sheet lead. Deadeye

straps are often used to secure a traveler line or mainsheet to

the hull. The traveler or mainsheet is knotted to prevent it from

coming through the eyes. \

WINCHES

Some

comments on winches have been made previously. The variety and

type of winches available to the sailor is enormous, but for the

small boat sailor, winches usually are restricted to the smaller

sizes used to control the jib and Genoa sheets. Winches can be

used for the halyards, boom vang, and mainsheets, if desired. On

small boats the cost is usually prohibitive, and the extra power

gained is not required, as these lines can be handled by the crew

or by other means, such as tackles, equally well.

|

FIG. 6-10 - The rudder is connected

to the boat with gudgeons (the fittings on the boat) and

pintles (the pin fittings on the rudder). They allow the

rudder to swing freely in order to steer the boat |

RUDDER FITTINGS

Small

sailboats usually have rudders which are called

“outboard” rudders because they hang onto the aft end

of the boat in full view. Boats which have rudders under the hull

and the rudder stock passing through the hull bottom are said to

have “inboard” rudders, but these are usually

associated with large boats. The ordinary small boat rudder is

attached to the boat with fittings that also allow the rudder to

pivot or turn. These fittings are called GUDGEONS and PINTLES.

These are arranged in pairs, with the gudgeons usually being

attached to the boat, and the pintles fastened to the rudder. The

pintles are strap-like fittings with the rudder fitting between

the straps, and with a pin at the forward edge which fits into

the “eye” of the gudgeons (see Fig. 6-10). As with most

fittings, many sizes and types are available. Often gudgeons and

pintles come in pairs which have a long pintle and a shorter one.

These types make it easier to put the rudder on the boat, as the

long pintle will be in position first, thereby acting as a guide

for the short one. If both pintles are the same length, both must

fit into the gudgeons at the same moment, which is frustrating at

times, especially when trying to place the rudder in position

when afloat. Because many small boat rudders are made of wood,

the tendency is for these to float up and out of the gudgeons, of

course, making for an immediate loss of steering and much

embarrassment. A device called a RUDDER STOP can be used to

prevent this from occuring. These are standard marine hardware

items very simple in nature.

|

|

| FIG. 6-11 - This

special factory-made kick-up rudder fitting incorporates

the rudder gudgeons and pintles. The fitting mounts to

the transom of the boat but allows the rudder to be

removed. This fitting is normally used on small boats

only. |

For small sailboats which land on

the beach, it is desirable to have the rudder “kick up”

when approaching shallow waters. Special “kick-up”

rudder fittings such as shown in Fig. 6-11 are available, which

also have the gudgeons and pintles attached as an integral unit,

and perform this function. With a little effort, you can make

your own “kick-up” rudder similar to the detail shown

in Fig. 6-12.

FIG. 6-12 - One method of making a

kick-up rudder using wood. When the pin is removed, the

rudder will automatically come up when hitting the beach. |

FIG. 6-13

- This tiller extension was made by merely cutting the

tiller in half at the forward end and fastening it with a

bolt. A more convenient type uses a swivel connection in

lieu of the bolt for universal action. The line shown is

a rope traveler which can be adjusted in length and is

secured to the jam cleat on the deck.

|

The rudder is controlled by a handle

called the TILLER. Sometimes the tiller passes through a

hole in the transom (back of the boat), but usually it is

located above the aft deck area and pivots up and down so

the crew can move about easily. The length of the tiller

is best determined in actual use, so it should be made

longer than necessary. It’s much easier to cut off a

long tiller than to add length to a short one. A device

recommended for easier control, especially when tacking

or sailing to windward, is a TILLER EXTENSION or

“hiking stick,” an example of which is shown in

Fig. 6-13. When sailing to windward in a small boat, the

boat usually heels considerably and the crew must lean

out to windward (or “hike out”) to counteract

this. In order to hang onto the tiller in this position,

an extension is required, fixed to the forward end of the

tiller and preferably fitted with a universal-type joint.

Naturally, the length of such a unit is best determined

in actual use, so it is best to get a long one which can

be cut, instead of getting one too short which can’t

be added to. |

Chapter 7

.....installing

fittings to the hull

GENERAL PRINCIPLES

Fittings

for the running and standing rigging must be capable of resisting

considerable strains. Therefore, it is always recommended that

fittings be through bolted whenever possible, with the fitting

being backed up with oversized solid blocking, especially on the

underside of thin fiberglass or plywood surfaces such as decks.

Use large flat washers under nuts, and bedding compound under the

fittings to prevent leaks. Where it is not possible to use

through bolts, then long screws of the largest possible shank

diameter should be used, driven into solid material below. These

rules apply to fittings wherever they may be required, whether on

cabin tops, cockpit soles, decks, or centerboard trunks.

On

wood hulls, finding solid material or providing solid backing

blocks is usually a simple matter. On fiberglass hulls, backing

blocks may have already been fitted when the hull was fabricated,

or the hull may have been reinforced with extra laminate build-up

in the area where fittings are to be located. If this hasn’t

been done in one form or the other, the builder must provide the

solid backing material to receive the fastenings for the fitting.

The wood blocks can be secured in place with a resin saturated

piece of fiberglass cloth or mat.

Fastenings

in all cases are preferably a non-corrosive type, which usually

means stainless steel, bronze, or at least hot dipped galvanized.

Do NOT, however, use hot dipped galvanized fastenings with, for

instance, bronze fittings, as the two metals are dissimilar and

corrosion will dissipate the fastener (at least in salt water). A

good rule-of-thumb is to use the same type material in the

fastenings as is used in the fitting, except that stainless steel

can be used to fasten into aluminum.

INSTALLING CHAINPLATES

Chainplates

may be located on the outside of the hull, usually along the

gunwale or hull side rail. For a neater appearance, however, it

is more common to have them located inside the hull, projecting

through the deck or cabin top. When they are located inside, this

usually means that they must be mounted in position prior to the

completion of the hull, and especially before the decking is

applied (see Fig. 7-1). The position of the chainplates should be

determined by the designer or manufacturer of the boat. This

position will usually be in conjunction with a main strength

member such as the hull sides, structural bulkhead, or other

longitudinal framing member. As with other fittings, solid

backing blocks, or extra reinforcing of the hull on fiberglass

boats, should be provided for mounting the chainplates.

FIG. 7-1 - If building a boat and

through-deck chainplates are called for, they should be

installed and bolted in place before the deck is applied.

The photo shows the chainplates bolted in position on

each side, protruding far enough above the deck line to

receive the turnbuckle or other stay hardware. (Glen-L 10

is shown) |

Chainplates

can be made of any strong metal as long as it is non-corrosive.

However, it is common to purchase ready made chainplates which

are usually made from stainless steel strap with holes usually

drilled in each end. If in doubt about which size chainplate to

use, always pick one that is larger and as long as practicable.

Always bolt the chainplate in position with at least two bolts

per unit. Be sure to let the top end of the chainplate extend far

enough above the deck or cabin top to allow the shrouds to be

attached. Where chainplates protrude through the deck or cabin

top, the hole should be sealed in a water proof mastic. Special

covers are available which match the ready-made chainplates to

cover the hole and “dress up” the area where the

chainplates pass through.

If

in doubt about the location of the chainplates, remember that

they are located as far outboard as possible, as far as

strengthening the mast is concerned. They must not, however,

interfere with sail handling; especially when a jib is used.

Also, if a single shroud on each side is used, the chainplates

are usually located a little aft of the mast. When upper and

lower shrouds are used, the chainplate for the upper shroud is

usually directly to the side of the mast. The chainplates for the

lower shrouds are then located a slight distance forward or aft

of this chainplate. When more than one chainplate is required per

side, they should be separated by a distance of at least several

inches in order to transfer the strains to the hull.

INSTALLING DECK FITTINGS

Deck

fittings such as blocks, cleats, winches, tracks, and related

items should be installed with bolts or long screws as previously

noted. Fastenings are usually not provided with the deck fittings

when purchased because the lengths will vary from boat to boat.

In

installing fittings such as for the mainsheet, it is advisable to

mock-up the arrangement before fastening anything permanently in

position, especially if you are not familiar with the

configuration, or are figuring out your own arrangement. Tape the

fittings in position and check to see that all fittings are in

the proper position and plane of reference for smooth operation.

It would be mighty embarrassing to find that a cam cleat, for

example, was fastened in backwards! While the designer will

probably note the positions of the various fittings, the best

locations for the fittings can be determined. Also check the

position of the various jam cleats which will be used to belay

the various sheets and halyards. Obviously these jam cleats must

have a "fair lead" to the line and be in a position so

the line will stay secure. Always locate jam cleats so the pull

of the line is at right angles to the line of the fastenings; not

in line with them which will tend to pull the cleat out.

If

your rig has a jib, care must be taken in locating the jib sheet

lead points; the position where the lines controlling the trim of

the jib intersects with the hull. Designers use a formula for

determining these positions and it has been noted previously and

in Fig. 5-16. The builder can also use this formula, but because

conditions of use, the sails, and boats in general vary, the best

method for determining jib sheet leads is by actually sailing the

boat and pinpointing the lead position while using the jib.

Admittedly, this may seem tedious and inconvenient, but on the

smaller boats with jibs up to about 50 square feet, it is really

not too much effort.

With

either method, once the correct point is determined, a fixed or

adjustable lead fitting can be installed. On small boats, a fixed

lead need consist of nothing more than a fairlead fastened to the

deck on each side for each jib sheet. On larger boats, or where

more efficiency is desired, a track can be used on either side

with a sliding fairlead. This method allows for variable trimming

of the sheet when underway, which is desirable when the

conditions of sailing change. This track for the jib would be

located so the mid-length of the track is positioned at the point

found to be most efficient. The track used for the jib is usually

at least 12" long. On larger boats that use a Genoa, a

separate track is provided for this sail, each side of the boat.

The lead point for the Genoa can be found by the trial-and-error

method, but because of the size of the sail, this is difficult,

to say the least. For this reason, it is better to use the

formula provided to determine the lead point for the Genoa, and

then use a longer length of track for the fairlead slide so that

variations are possible. In most cases the Genoa track is located

fairly parallel along the sheer rail as far outboard as

practical. Track stops must be provided for all jib and Genoa

tracks at the ends so the slides will not come off when underway.

When

winches are required for handling sheets and halyards, their

position must be carefully determined. Halyard winches are

generally fastened to the mast, but are really not considered

necessary equipment on the size boats being considered here. This

leaves winches which are used for the jib or Genoa sheets. Here

again the position of the winches will usually be noted by the

designer, but as stated previously, this will be an

approximation, and the exact position for the winches is best

determined in use once the sheet lead points are known, or at

least mocked-up.

In

locating winches, several things must be considered. First, the

winch must be near at hand and convenient to use. If it has a

handle, clearance must be allowed for a full circle swing.

Winches may be located on deck, but it is common to raise them up

on blocking in order to clear cockpit coamings. If the winch is

blocked up, this blocking should be angled so the lead of the

sheet from the track is fairly horizontal to the winch. A cleat

is always used to secure the sheet after taking turns around the

winch. These cleats are preferably in a horizontal plane with the

winch as well.

When

installing “outboard” rudders on the transom, gudgeons

and pintles, as described in the previous chapter, are used.

Sometimes inboard rudders are used, and these are usually

detailed on the plans by the designer. With “outboard”

rudders, most commonly the pintles are bolted to the rudder. The

gudgeons are then screwed or bolted to the transom. Most boats

use a set of two each, and these should be spaced as far apart as

possible to distribute the strain on the rudder. Install a rudder

stop if there appears to be any tendency for the rudder to float

up and out of the gudgeons. Any number of types of rudder stops

are available, some of which may be integral with the rudder

fittings. Another method which can be used but is not very

seaman-like is to bend the pintles with pliers so they fit

tighter in the gudgeons.

|

|

|

|

| FIG. 7-2 through 7-5 -

Two types of mast steps are shown for use with aluminum

spars. The first pivots; the aft corner of the mast at

the base is radiused to allow clearance when pivoting.

The exploded view shows an internal stiffener used on

light masts to provide bearing for the bolt. The second

type of step is fixed to the deck and the mast sets onto

it. It is held in position by the stays. |

Installing

the mast step may not require any fittings if the mast is to be

stepped through the deck and provisions have been made in the

hull structure. However, with masts that are to be stepped on the

deck or cabin top, a means of securing the mast is required, and

this is usually by the mast step fitting such as shown by Figs.

7-2, 7-4, and 7-5. As noted previously, several types of steps

are available. Depending on the design, reinforcing below the

mast step may be required, such as a mast stanchion or large deck

beam. The reason for this extra support is that the mast is in

direct compression onto the boat and the considerable strain must

be transferred throughout as large an area of the structure as

possible. So it is important that the mast step be located

directly over these strength members and rigidly mounted. Mast

steps are preferably through bolted in any case.

Chapter 8

.....outfitting

spars

INSTALLING FITTINGS

As

noted previously, small boat spars are made of wood or aluminum.

Wood spars may be either solid or hollow, while aluminum spars

are hollow. Fittings on wood spars are usually screwed with wood

screws or through bolted. If through bolted, the bolts should

pass through solid wood blocking in hollow spars. Fittings on

aluminum spars can be bolted, but the number of through bolts in

an aluminum spar should be kept to a minimum, and the bolts

should never be tightened to a point that will collapse the spar.

Nuts on through bolts should be locked with lock washers or

self-locking nuts to prevent the nut from working free. Another

method to lock the nut is to cut off the end of the bolt just

above the nut and, with a center punch, drive the punch hard into

the center of the end of the bolt. This will spread out the metal

in the bolt and the nut as well, jamming them in position. Most

fittings on aluminum spars are secured with self-threading sheet

metal screws that should be of stainless steel. In fact, all

fastenings through the aluminum should be stainless steel to

prevent corrosion of the spar that can occur when dissimilar

metals are in contact in marine conditions. Lubricate sheet metal

screws with oil before driving. It is possible to use rivets to

fasten parts to the aluminum spars, especially with “pop

rivets” if you have the tool. These can be used on items

such as tracks or flat base fittings, but in any case the rivets

should be stainless steel or aluminum, and the hole of the rivet

filled with epoxy cement filler. If using aluminum pop rivets,

use plenty because they are not as strong as the stainless steel

type. Where plastic fittings are used, such as fairleads, these

can be secured with epoxy glue. When drilling for bolts in either

wood or aluminum, the hole should not be a sloppy fit, but should

be snug. Screw holes for wood screws must also be of the correct

size, and lead holes for the self-threading screws in aluminum

spars must be of the correct size required for the screw, which

is always less than the size of the screw.

|

FIG. 8-1 - A Nylon fairlead, such

as used for the exit point of internal halyards, is

simple to install. Just drill a hole of the right size in

the mast and use a two-part epoxy adhesive to secure the

fitting in position. |

Where

internal halyards are required, it is best to lead wires through

the mast before outfitting so the halyards can be attached to

these for later reeving. On hollow wood masts, it is easiest to

do this before assembling the mast. The halyards, when run

internally, exit the mast near the base. The exit point must be

fitted with some type of fairlead. This may consist of merely a

hole with a plastic fairlead fitting such as shown in Fig. 8-1 to

prevent chafing the halyard, or can be the more elaborate coaming

pulley or sheave box arrangement. In any case, one exit is

required for each halyard, and it is convenient to locate the

exit for the mainsail halyard on the aft or port side of the

mast, and the jib halyard exit on the forward or starboard side

of the mast to avoid confusion. Some skippers use different

colored lines for halyards to keep them separated. If using wire

rope for the halyards, all sheaves must be for use with wire

rope, and a fairlead without a sheave should preferably not be

used. It is possible to bring the halyards through the mast base

where they can be concealed in the cabin, or in the forward cuddy

below decks space. This arrangement does have merits especially

with regard to clutter. One problem with the arrangement,

however, is that there is no good way of keeping water from

entering the hull through the holes required, which is especially

critical on cabin boats.

With

aluminum spars, most of the other fittings, such as the masthead

fitting, or boom gooseneck fittings are made up of aluminum

castings which fit the spar extrusion (see Figs. 8-2, 8-3, 8-4,

and 8-5). Once the lengths of the spars are known, these fittings

are inserted in position and screwed or riveted in place.

Aluminum spars are easily cut with a hacksaw if oversize, and

rough edges filed clean. When aluminum is used for the boom, it

is a simple matter to have roller reefing, as the roller reefing

gooseneck can be incorporated in the hollow extrusion. When using

aluminum castings for aluminum spars, it is often necessary to

file off rough edges. This is normal, and because of the relative

softness of the metal, takes little effort. Also, a little oil or

wax will make the fittings slip into the extrusion more easily.

Fittings on wood spars are fastened with wood screws or through

bolted. Goosenecks for wood booms usually have tang or strap-like

members into which the boom fits. These tangs can usually be

spread apart somewhat to suit the thickness of the boom. The

gooseneck is bolted through the boom as are boom bails where

required.

Masthead

fittings should be detailed by the designer of boats with wood

masts, and the larger the boat, the more elaborate the fitting.

On simple mastheads which have only one halyard, all that is

required is a sheave installed in a groove at the top of the

mast. A similar sheave may be used at the clew outhaul on the

boom. These sheaves use a pin axle driven through a hole, and the

ends are peened (flattened) over to keep it in position. Sheaves

are usually synthetic plastic material or metal where wire rope

is used.

BOLT ROPE GROOVES

On

spars which use a groove for the bolt rope of the sail, there

must be a means by which the bolt rope can enter the groove. On

wood spars, an area must be relieved using the method described

later, or by the directions in the plans provided with the boat,

if you are building your own boat. On aluminum spars which use a

groove, a portion of the mast must be filed away with a coarse

file (see Figs. 8-6 and 8-7). Do not cut away the groove

excessively, and make sure all rough edges are smooth to prevent

wear on the sail. A small fine file or rotary grinder plus emery

cloth will do the job. Look at the end of the mast to determine

the amount to remove. The length and position of the cutaway

areas should be provided by the designer of the boat, or by the

spar supplier. If the position or length required is not given,

it can be determined by using the sail as a guide. Hold the sail

so the top or head is 6" to 8" below the top of the

mast, and stretch the bolt rope tightly along the mast. Mark the

position where the tack of the sail falls along the mast, and

relieve an area 5" to 12" above the tack, both for

entry of the bolt rope and the gooseneck slide fitting. Remember

that the relieved portion must be above the gooseneck when the

gooseneck is positioned when pulled down by the downhaul (see Fig. 3-15).

8-6 |

8-7 |

| FIG. 8-6 & 8-7 -

Goosenecks used with grooved aluminum spars must be

relieved in order to fit the gooseneck into the groove.

Although a wood boom is shown, it could be of aluminum

also. The relieved portion is also required for the bolt

rope of the sail so the relieved area must be carefully

determined. When the boom is pulled down by the downhaul,

it cannot be in the relieved area; it must be below it as

shown by Fig.

3-15. |